The Fundamentals of Mechanical Watch Accuracy

Understanding the fundamentals of mechanical watch accuracy is crucial for any enthusiast or professional. Accuracy in mechanical watches is a measure of how well the timepiece keeps time, differing from one watch to another based on various intrinsic and extrinsic factors.

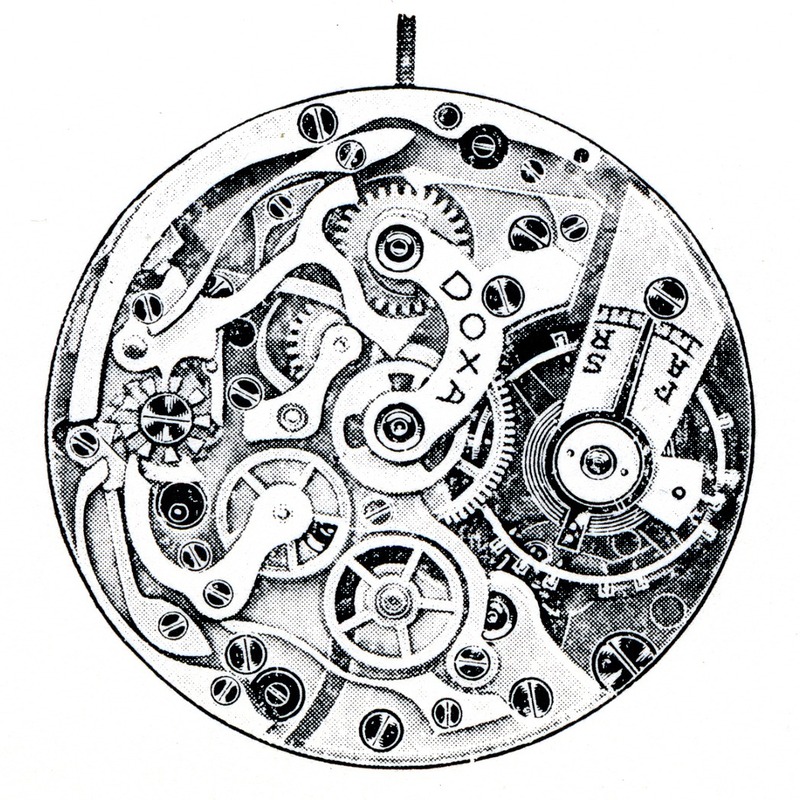

How Mechanical Watches Work

Mechanical watches operate without electricity, relying on a complex system of springs and gears. The movement, or caliber, is the heart of the watch. It contains the mainspring, which stores energy, and the gear train, which transmits this energy to the hands. A regulating organ, often an escapement and a balance wheel, controls the energy release, ensuring precise timekeeping.

Factors Affecting Watch Accuracy

Several factors influence the accuracy of a mechanical watch. These include the quality of the movement’s assembly, the purity and stability of the materials used, and the watch’s exposure to external elements like gravity, shocks, and magnetic fields. Wear and tear over time also plays a part, highlighting the need for regular maintenance to preserve optimal performance.

The Impact of Movement Design on Accuracy

The design of mechanical watch movements is a critical factor affecting their accuracy. High-precision timepieces often feature expertly engineered components designed to reduce errors in timekeeping.

The Role of Escapement Mechanisms

Escapement mechanisms are central to a watch’s movement. They manage the release of energy from the mainspring to the gear train. A precise escapement ensures the balance wheel oscillates at a constant rate. This helps the watch keep accurate time. Innovations in escapement design, such as the co-axial escapement, reduce friction and wear. This results in better long-term accuracy and fewer maintenance needs.

Innovations in Movement Technology

Recent advancements have further improved mechanical watch accuracy. Silicon components, for example, are less affected by magnetic fields and temperature changes. This makes watches more reliable. New alloys for springs and other parts have also been introduced. These materials maintain their shape and elasticity better, even under stress. Movement technology continues to evolve, with a focus on materials and designs that enhance precision and reliability.

Material Innovations Improving Watch Precision

Innovations in materials play a pivotal role in enhancing the precision of mechanical watches. Over time, watchmakers have introduced groundbreaking materials that significantly reduce the impact of factors that traditionally affected watch accuracy.

Silicon Components in Watchmaking

The introduction of silicon components in watchmaking marks a revolutionary step. Silicon is immune to magnetic disturbances, a common issue for mechanical watches. Unlike metal parts, silicon does not rust, is lighter, and is less prone to temperature fluctuations. These properties lead to a more consistent performance, safeguarding watch precision in a variety of conditions. The use of silicon has been crucial in manufacturing hairsprings and escape wheels, vital parts in the regulation of movement.

Advancements in Metals and Alloys

Beyond silicon, advancements in metals and alloys have significantly contributed to watch precision. New alloys, like Parachrom and Nivarox, offer superior resistance to shocks and temperature changes. Their resilience ensures the movement’s critical components maintain their shape and elasticity. Mechanical watches with these advanced materials experience fewer time deviations, even after exposure to stress factors. This innovation in metals and alloys is essential for the long-term accuracy and durability of high-quality timepieces.

Calibration and Maintenance for Optimal Performance

Maintaining mechanical watch accuracy isn’t just about internal components. Regular calibration and maintenance play vital roles, too.

The Importance of Regular Servicing

Just like any high-precision instrument, a mechanical watch requires regular servicing to perform at its best. Neglecting maintenance leads to diminished accuracy and potentially costly repairs. Servicing involves cleaning, lubricating, and replacing worn parts. Experts recommend a check-up every 3 to 5 years. This ensures that the tiny gears and springs work in harmony, maintaining optimal performance.

Fine-Tuning a Mechanical Watch

Fine-tuning, or regulating, is the process of adjusting a watch to run within optimal timekeeping standards. Professional watchmakers perform this delicate task, making micro-adjustments to the balance wheel and escapement. It’s a critical step in addressing any discrepancies in timekeeping. This precision work, in combination with regular servicing, keeps the mechanical watch ticking accurately over time.

External Factors Influencing Watch Accuracy

Mechanical watch accuracy is not only shaped by its internal makeup but also by external forces.

Temperature Variations and Their Effects

Watches react to temperature changes. Heat can expand a watch’s metal parts, speeding up the mechanism. Cold can do the opposite, slowing it down. This impacts how well the watch keeps time. To counter this, watchmakers use materials like silicon that resist temperature effects.

How Magnets Can Affect Your Watch

Magnetic fields are another challenge. They can pull on a watch’s metal parts, altering the movement. This disrupts accuracy. Today, watchmakers design watches with anti-magnetic properties. They use non-ferrous materials to keep timekeeping steady, even when exposed to magnets.

The Pursuit of Perfection: Chronometer Certification

In the world of mechanical watch accuracy, chronometer certification stands as a benchmark for excellence. Timepieces that earn this prestigious recognition have undergone rigorous testing to meet supremely high standards of precision.

Understanding COSC Standards

COSC, short for Contr?le Officiel Suisse des Chronomètres, is an organization that certifies the accuracy and precision of watches in Switzerland. Watches aspiring for this title face strict scrutiny over several days, in different positions and temperatures. To achieve certification, a watch must maintain exceptional accuracy, generally between -4/+6 seconds per day. COSC’s rigorous approach is crucial for brands striving to mark their timepieces as among the most accurate in the world.

The Quest for Ultra-Precise Timekeeping

The pursuit of ultra-precise timekeeping is relentless. Watchmakers continually push the limits with innovative materials and designs, all to enhance the accuracy of their mechanical watches. Achieving COSC certification is the sought-after goal that guarantees a watch’s performance. It is a symbol of unmatched precision, an assurance to the wearer that their timepiece operates within the tightest tolerances of timekeeping.

The Role of Craftsmanship in Mechanical Watch Precision

Craftsmanship plays a key part in ensuring the precision of a mechanical watch. Master watchmakers devote their skill to every detail, from the smallest gear to the finishing of the watch face. The human touch is vital and when expert hands guide the process, the outcome is a timepiece of exceptional accuracy and beauty. Crafting a watch is not just a science; it’s also an art that impacts its precision.

Hand Finishing and Its Contribution to Accuracy

The hand-finishing of a watch, known as ‘anglage’, involves polishing and beveling the edges of its components. This reduces friction between moving parts, leading to smoother operation and better accuracy. Skilled artisans ensure that even unseen parts meet high standards. This attention to detail extends the life of the watch and maintains its performance over time.

The Art of Watch Assembly and Its Impact on Precision

In the art of watch assembly, precision is paramount. Each movement, no matter how small, must fit perfectly. Expert watchmakers assemble with care, ensuring that each part is placed with precision. This exact process prevents future inaccuracies. The level of craftsmanship in assembly not only defines a watch’s accuracy but also its value and prestige.