Part 1: Understanding the Mechanism of a Mechanical Watch

A mechanical watch is a timepiece that uses a mechanical mechanism to measure the passage of time. Unlike their quartz counterparts, which use batteries and electronic circuits to keep time, mechanical watches rely on a series of intricate gears and springs to function. Understanding the inner workings of a mechanical watch is crucial when it comes to setting it with precision.

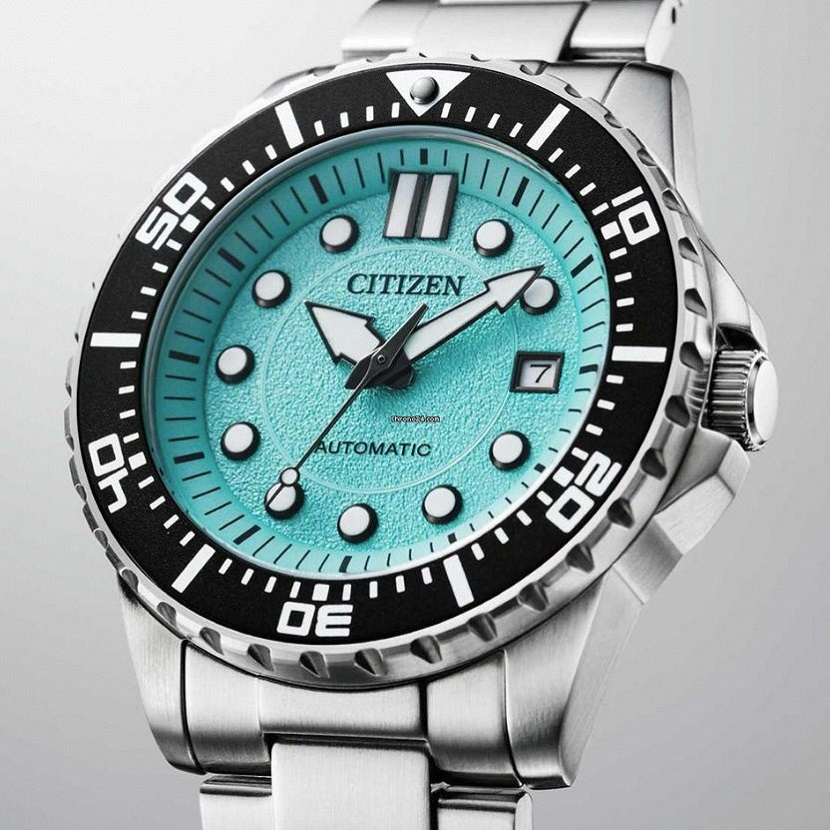

1. The Main Components:

A mechanical watch consists of several key components, including the mainspring, the balance wheel, the escapement, and the gear train. The mainspring is the energy source of the watch, providing power to the movement. The balance wheel oscillates back and forth, regulating the speed at which the gears turn. The escapement controls the release of energy from the mainspring, while the gear train transmits that energy to the hands of the watch, allowing them to move and keep time.

2. The Role of the Crown:

The crown in a mechanical watch is a crucial component that controls both winding and time setting functions. When the crown is pulled out, it essentially disengages the gear train from the movement, which is necessary to accurately adjust the time. This disengagement ensures that the movement is not disturbed while the time is being set. Understanding the proper position and function of the crown is key to avoid putting unnecessary strain on the watch’s movement and gears. It also facilitates precision in setting the time, ensuring that the watch keeps accurate time over extended periods.

Knowing how to operate the crown with the correct sequence of movements is fundamental. Understanding the impact it has on the working of the watch is essential for anyone looking to master the art of setting a mechanical watch with precision. This knowledge is also essential for the longevity of the timepiece. It helps to prevent any potential damage to the movement, ensuring the watch functions optimally for years to come. Therefore, understanding the interaction of the crown with the movement and its role in setting the time accurately is crucial for anyone who appreciates the craftsmanship and intricacy of mechanical watches.

Part 2: Winding a Mechanical Watch

Winding a mechanical watch is the process of tightening the mainspring to ensure that the watch has enough power to run. While some modern mechanical watches are self-winding, meaning they can be powered by the movement of the wearer’s arm, many traditional models need to be wound manually.

1. Understanding the Winding Direction:

Understanding the correct winding direction for a mechanical watch is vital for its proper maintenance and functionality. Most mechanical watches are designed to be wound in a clockwise direction. This action tightens the mainspring, which is responsible for powering the watch. However, there are exceptions. There are specific models known as left-handed or reverse watches that necessitate a counterclockwise winding motion. Knowing the correct winding direction for your particular watch is crucial to avoid causing damage to the delicate internal mechanisms.

Winding a watch in the wrong direction could potentially cause the gears and springs to become misaligned or, in extreme cases, break. This is why it’s crucial to ascertain the winding direction before attempting to wind the watch. Most watches come with instructions specifying the correct winding direction, and it’s essential to follow these guidelines diligently.

Additionally, if the watch is left unwound for an extended period, winding it too forcefully or in the wrong direction can put unnecessary strain on the movement. It’s important to wind the watch gently with a consistent motion. Overwinding can also lead to issues with the timekeeping accuracy of the watch.

By knowing the specific winding requirements of your mechanical watch, you can ensure that it operates smoothly and accurately for years to come. This attention to detail not only enhances the longevity and reliability of the timepiece but also reflects a deeper appreciation for the meticulous craftsmanship that goes into creating mechanical watches. Therefore, understanding and adhering to the correct winding direction is a fundamental aspect of mastering the art of maintaining and caring for a mechanical watch.

2. Consistency is Key:

Winding a mechanical watch with a consistent, gentle motion is crucial to avoid placing undue stress on its delicate internal components. Overwinding or applying excessive force can lead to damage, impacting the watch’s accuracy and longevity. To maintain a consistent power reserve, it’s advisable to wind the watch at the same time each day. This approach not only ensures that the watch keeps accurate time but also prevents the mainspring from being excessively wound, which could lead to unnecessary wear and tear. By adhering to this careful and consistent approach, watch enthusiasts can prolong the lifespan of their mechanical timepieces, appreciating their precision and craftsmanship for years to come.

Part 3: Setting the Time and Date

Once the mainspring of a mechanical watch has been wound, the next step is to set the time and date. This process requires careful attention to detail to ensure that the watch keeps accurate time and the date changes smoothly.

1. Time Setting:

Setting the time on a mechanical watch involves pulling the crown out to its furthest position and turning it in the designated direction until the hands align with the correct time. Precise time setting is crucial as even a slight misalignment can impact the watch’s accuracy. This process requires attention to detail and a steady hand to ensure that the watch keeps accurate time. By setting the time accurately, the wearer can appreciate the precision and craftsmanship of the mechanical watch. It ensures that it functions reliably. Setting the time precisely reflects an understanding and respect for the intricate mechanics of the timepiece. It enhances the overall experience of owning and using a mechanical watch. Therefore, taking the time to set the watch accurately is a fundamental aspect of mastering the art of caring for a mechanical watch.

2. Date Setting:

If your mechanical watch features a date complication, setting the date involves an additional step. Some mechanical watches have a quick-set date function, which allows the date to be adjusted independently of the time. Others require the time to be advanced past midnight to change the date, then set the time backward to the correct position. Understanding the date-setting mechanism of your watch is essential for adjusting it correctly.

Part 4: Maintaining Accuracy and Care

After setting a mechanical watch with precision, it’s important to take steps to maintain its accuracy and ensure its longevity. Regular maintenance and proper care can go a long way in the longevity of a mechanical watch.

1. Regular Servicing:

Mechanical watches require periodic servicing by a professional watchmaker to keep them in top condition. This typically involves disassembling the movement, cleaning and lubricating the parts, and making any necessary adjustments to ensure the watch keeps accurate time. Most manufacturers recommend servicing a mechanical watch every 3-5 years, depending on its age and usage.

2. Avoiding Magnetization:

Magnetic fields can interfere with the movement of a mechanical watch, causing it to run fast or slow. It’s important to keep a mechanical watch away from strong magnetic sources, such as speakers, cellphones, and magnetic clasps, to prevent magnetization. If a watch becomes magnetized, it should be demagnetized by a professional watchmaker to restore its accuracy.

In conclusion, mastering the art of setting a mechanical watch with precision involves a deep understanding of its inner workings, careful winding, accurate time and date setting, and proper maintenance. With this knowledge and attention to detail, watch enthusiasts can enjoy the timeless beauty and craftsmanship of mechanical timepieces for years to come.